Rubber Peptizer DBD

Classification:

Product Introduction

Product Details

Chemical Name: 2,2'-Dithiobisbenzanilide;

2,2′-Dibenzamido diphphenyl disulfide;Dithio-bisbenzanilide

Molecular Formula: C26H20N2O2S2

Molecular Weight: 456.58

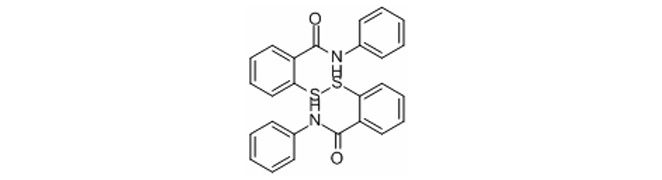

Chemical Structure:

CAS NO: 135-57-9

Specification:

|

Item |

Index |

|

Appearance |

Light-Yellow powder |

|

Melting.Point. ℃≥ |

137.0 |

|

Loss on drying %≤ |

0.50 |

|

Ash %≤ |

0.50 |

|

Residues on 150m sieve %≤ |

0.30 |

|

Content %≥ |

97 |

Properties: Light yellow powder, low poison, no-pollution, Soluble in benzene, ethanol, acetone and other organic solvents, insoluble in water. Touch the skin can cause dermatitis. Best storage stability.

Application: It can be used in the natural rubber and synthetic rubber or alloy rubber. It can be added into peptizing machine with crude rubber, with the best operational temperature is 155°C±5°C. or added into blender mill at the first time after cracking. Dosage is 0.1 to 0.5 portions.

Packaging:25kg plastic woven bag, paper with plastic film bag, kraft paper bag .

Storage: The product should be stored in a dry and cooling place with good ventilation. Avoid exposure to direct sunlight.

Key words:

Rubber Peptizer DBD

Online message

Leave a message immediately and get the product quotation free of charge. We will arrange the specialist to contact you as soon as possible.